At Michigan Foam Products LLC, with virtually unlimited EPS design options, we are aware that one size (or hundreds of sizes) do not fit all. Ideas are what makes Michigan Foam Products the EPS source to trust. We have the ability to give you quick turn-around times when your project demands it. With the assistance of our highly experienced Design and Engineering Department, you can have a specialty EPS solution or product sample developed just for you. We have done everything from simple shapes to very complex shapes and designs. Michigan Foam Products has the ability to design and fabricate just about anything you can imagine. We offer an opportunity for your idea to be tested as a prototype first. This sample tryout is very beneficial for getting it right. We will work closely with you every step of the way to make sure it’s exactly what you need.

Michigan Foam Products LLC is very fortunate to have so many talented and creative customers including fortune 500 companies, movie studios, and individual artisans who can take a piece of our expanded polystyrene and turn it into a unique entity all its own. Many of these artists have taken EPS to the next level. We are continually amazed at the genius in which a simple block of EPS foam can be turned into an elaborate movie background, light-weight structures, or beautiful display models just to name a few.

Specialty EPS also includes more than just measurements. We also give the customer many varieties of EPS foam densities that go beyond the ordinary weights of foam density you typically receive in a standard item quote. Imagination dictates the end result. The customer has many options to choose from, one of them being able to reduce the cost of the product by reducing foam density and maintaining what’s necessary for the application.

Michigan Foam Products use SolidWorks® CAD software with the capability to read most file types of computer aided design files, including DXF, IGES, and DWG.

- The maximum size foam block that Michigan Foam products produces from its Hirsch-Gruppe block mold is 196" x 37" x 61"

- The maximum length contour part we can produce is 120"

- In some instances, expanded polystyrene (eps) block material must be cured 72 hours minimum before processing to your requirements

- For specific sizes please contact us!

Past projects

expanded polystyrene

EPS Foam Airplane Display

This massive display prop was made from Michigan Foam Products EPS by Michael Wren of Wrensong Studio. This unique design was constructed for a local church

Cruise Ship Miniature Golf Courses

Aboard massive cruise liners in the Caribbean, you can enjoy a game of miniature golf on a course made with EPS foam underlayment from Michigan

Movie Props for “Real Steel” 2011 (Dreamworks®)

In 2011, Michigan Foam EPS was used for the Sci-Fi Dreamworks® movie “Real Steel” starring Hugh Jackman. Filmed almost entirely in Michigan, the movie special effects

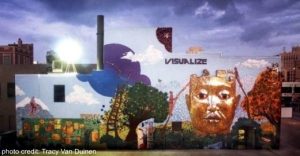

2011 Grand Rapids Art Prize 2nd Place

Competing in the 2-D category of the City of Grand Rapids Art Prize competition, Tracy Van Duinen of Meta-Phorist used Michigan Foam EPS to make

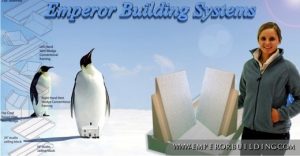

Emperor Building System

The Emperor Building System EPS foam is fabricated entirely at Michigan Foam Products. This innovative insulation system is made with 50% recycled EPS foam, and

Mono Slab EZ Form LLC. – Island Park, Idaho

The Mono Slab EZ Form is a new ICF concrete form system that is simple to set up, and requires very minimal takedown. Mono Slab